https://www.cnhfprecision.com/new_arrivals/2377.html

● Glass Water Bottle with Protective Sleeve

A glass carafe takes your soda maker machine to another level, while it lasts for a much longer working life than PET bottles. An extra stainless steel protective cover protects users from any exploding possibility of glass bottles. Safety is the first and basic factor of a soda maker.

● Wild-mouth Carbonating Bottle

Wide-mouth glass carafe upgrades your carbonator to another level while obtains the capacity of adding bubbles to fresh fruits and vegetables besides pure water. Its wide mouth characteristic makes it much easy for consumers to rinse.

Healthier, Cheaper, Convenient, Eco-friendly, DIY

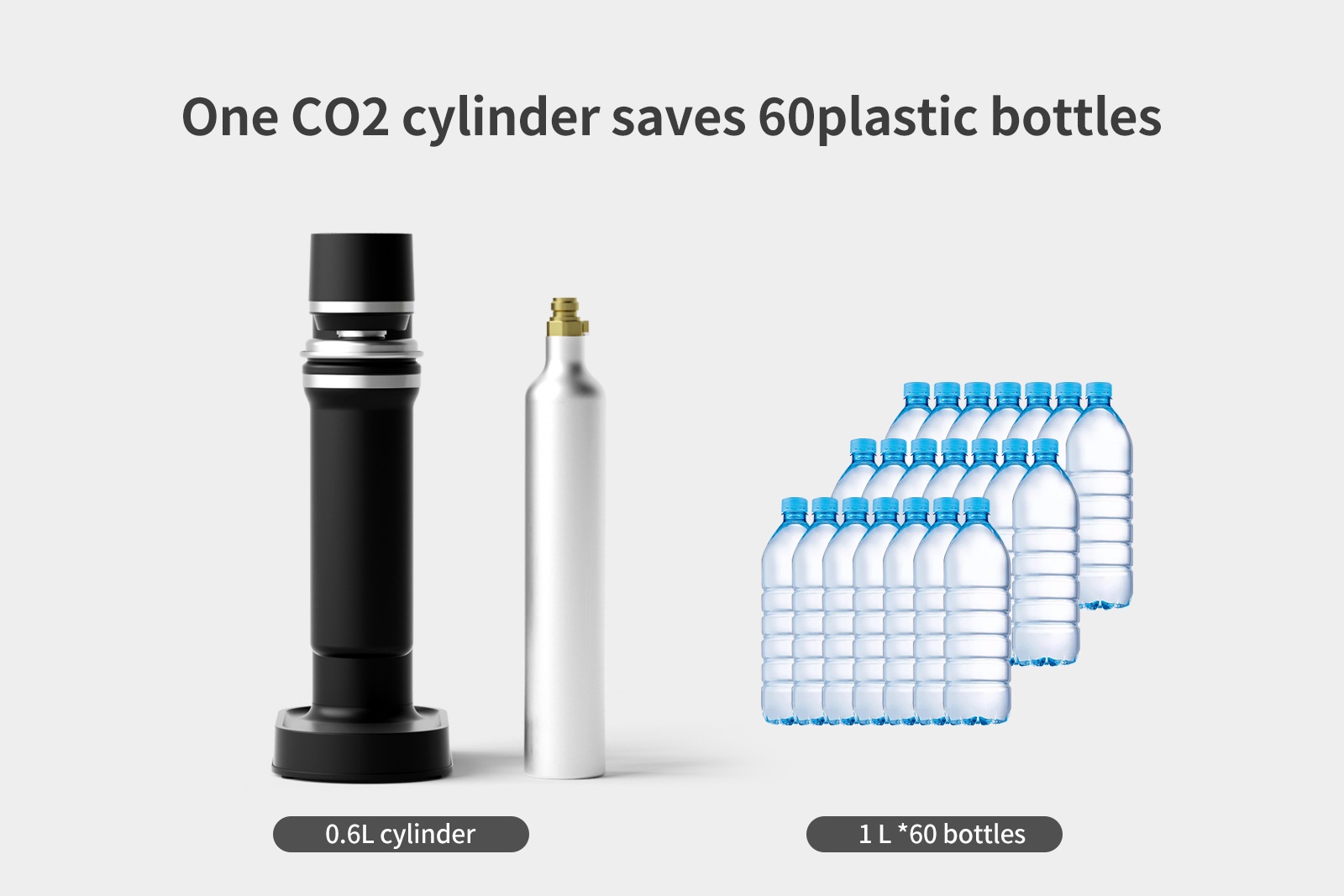

Deliver great-tasting alternatives to traditional sugar-heavy sodas, whilst dramatically reduces repetitive plastic consumption. Tailor the amount of 'sparkle' and recipe as you like.

Various Material Options for Water Bottle

Materials can be BPA-free PET, dishwasher-safe tritan, stainless steel, glass carafe (with stainless steel protective cover). All materials are reusable and food-grade.

Quality-centric Approach

Materials can be BPA-free PET, dishwasher-safe tritan, stainless steel, glass carafe(with stainless steel protective cover). All materials are reusable and food-grade.

Compatibility

Compatible with many other screw-in 60L CO2 gas cylinders, except for Australia and New Zealand. However, we are also capable of customizing new molds for the Australia and New Zealand markets. Please let us know if needed. For wholesalers or retailers, you can purchase empty cylinders from us and fill them up locally, or purchase soda maker machines only and let consumers buy gas cylinders from local supermarkets, petrol stations, and homeware stores such as Target, Kmart, and Big W.

Related products

-

Small Scale PE PP HDPE LDPE Films Bags Rigid Plastic Granulators Recycling Pelletizing Machine

Contact UsThis is multifunctional small plastic pelletizing line. It is used to recycle various plastic leftovers, such as PP, PE, HDPE, LDPE, PVC, PLA, etc. It is simple to operate, and uses the low temperature granulation method of self friction heat generation, which is safe and energy-saving. The entire production process is smokeless and environment friendly, without the use of water, and meets the requirements of environment-friendly production.

-

Waste plastic or Modified PE Pelletizing

Contact UsThe waste plastic or modified PE material is fed into the machine through a hopper. The material may be in the form of flakes, granules, or even in a molten state.

-

FS-V-F240 Injection valve

Contact UsFS-V-F240 series drip-proof valve is suitable for direct injection of lithium battery which can efficiently avoid liquid dropping and hanging.

-

UT 1.6523/8620/20CrNiMoA Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Blockund Bar

Contact Us1.6523 Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Block/Round Bar

Reviews

There are no reviews yet.