3G Intelligent Fin Machine

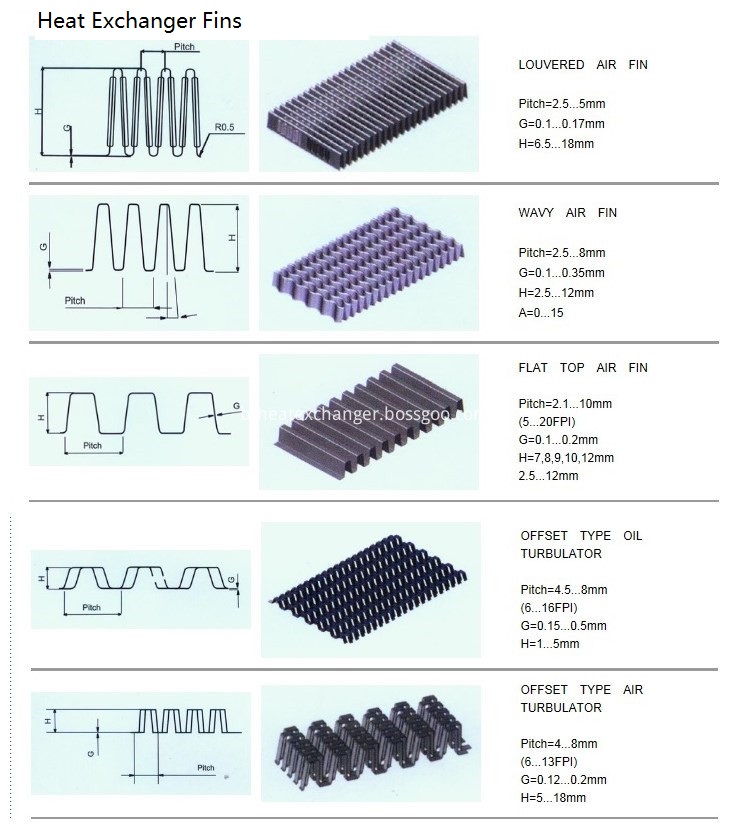

The Fin Machine is a device that directly processes the foil into various types of heat transfer fins. On the basis of the first and second generation fin machine, the third generation 3G fin machine mainly consists of 5 parts: automatic feeder, oiling device, Host machine stamping, servo control fin cutting machine and independent electrical control box. The full set of 3G automatic fin production line adopts PLC intelligent automatic control, which has the functions of automatic feeding, automatic fin forming, automatic fin cutting and electrical adjustment of mold installation. When producing different height fins with the same mold (suitable for the same fin pitch and different heights), the data can be set on the display screen for quick positioning and easy operation which greatly saves the time of debugging molds.

Core Components: Plc, Motor

Core Selling Point: Easy To Operate

Applicable Industry: Manufacturing Plant

Place Of Origin: China

Video Factory Inspection: Provided

Marketing Type: New Product 2020

Packaging: Pallet/Case

Productivity: 300 Sets/Month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 300 Sets/Month

Certificate: CE

HS Code: 847480

Port: Shanghai,Ningbo

Payment Type: T/T

Incoterm: FOB,CFR,CIF,EXW

Packaging & Delivery

-

Selling Units:Set/Sets

-

Package Type:Pallet/Case

-

The Fin Machine is a device that directly processes the foil into various types of heat transfer fins. On the basis of the first and second generation fin machine, the third generation 3G fin machine mainly consists of 5 parts: automatic feeder, oiling device, Host machine stamping, servo control fin cutting machine and independent electrical control box. The full set of 3G automatic fin production line adopts PLC intelligent automatic control, which has the functions of automatic feeding, automatic fin forming, automatic fin cutting and electrical adjustment of mold installation. When producing different height fins with the same mold (suitable for the same fin pitch and different heights), the data can be set on the display screen for quick positioning and easy operation which greatly saves the time of debugging molds.

-

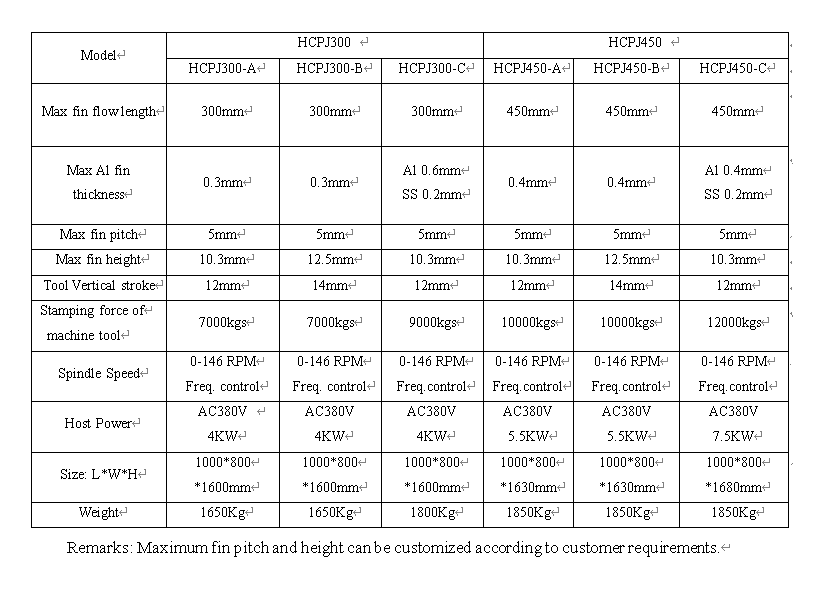

Fin Forming Machine- Main technical parameters and specifications

-

Related products

-

Optimizing Cross Cut Saw MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line. -

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.

-

Water-cooled cabinet

Contact UsThe water-cooled cabinet condenser uses a water-cooled condenser, and the evaporator directly cools the air.

-

NEW GLASS SODA MAKER BEST CARBONATOR(GLASS BOTTLE) NEW ARRIVALS SODA STREAM MAKER HOUSEHOLD SPARKLING WATER MAKER WITH GLASS BOTTLE

Contact UsNEW GLASS SODA MAKER BEST CARBONATOR(GLASS BOTTLE) NEW ARRIVALS SODA STREAM MAKER HOUSEHOLD SPARKLING WATER MAKER WITH GLASS BOTTLE

Reviews

There are no reviews yet.