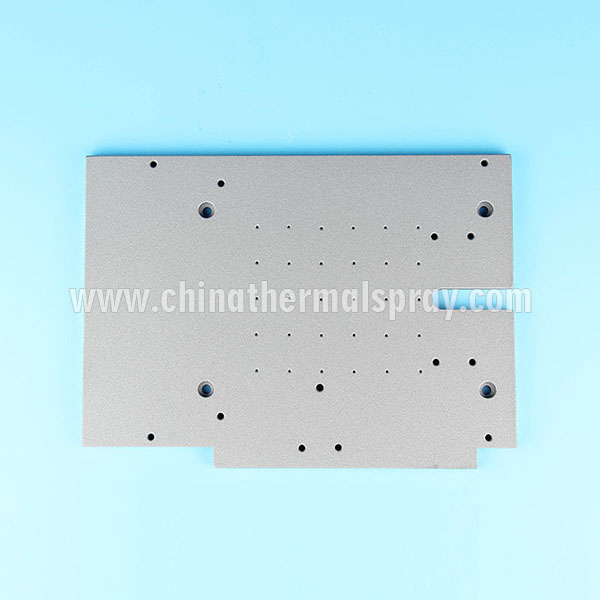

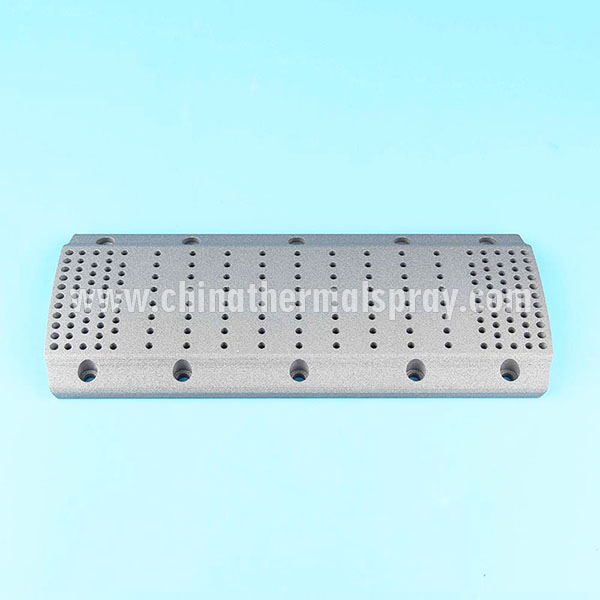

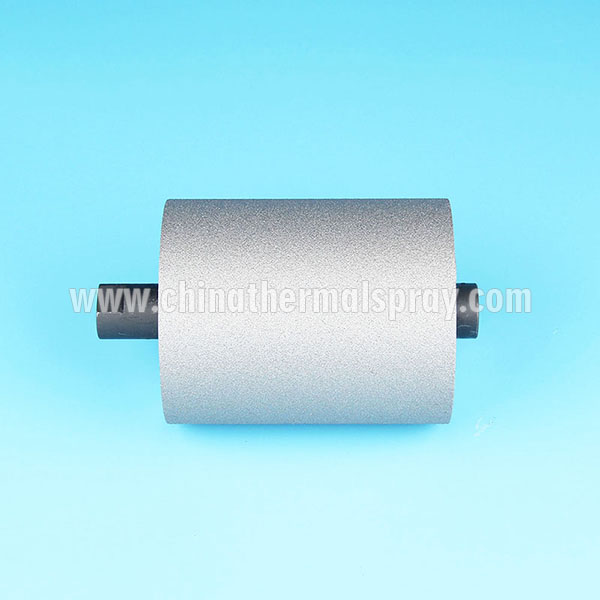

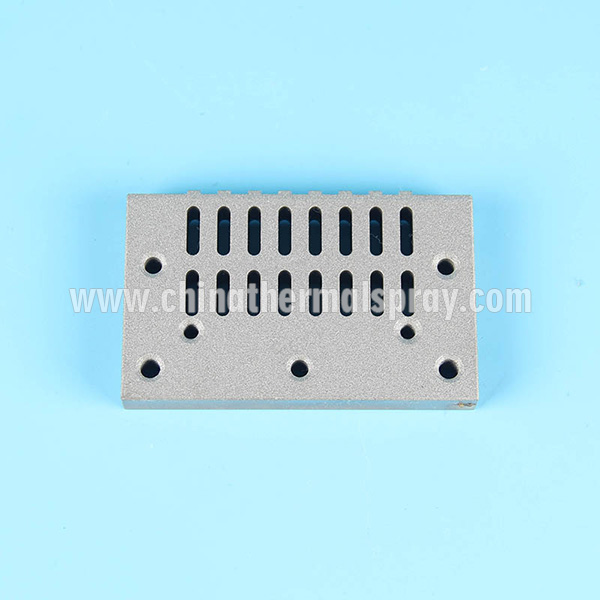

Anti-Sticking Wear-Resistant Coating

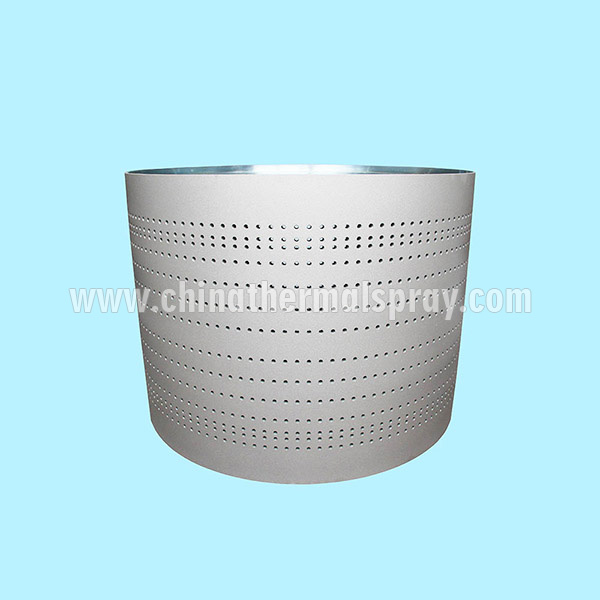

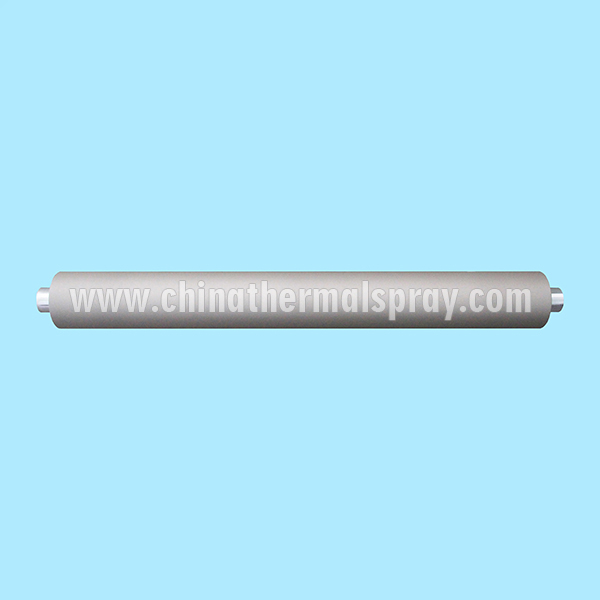

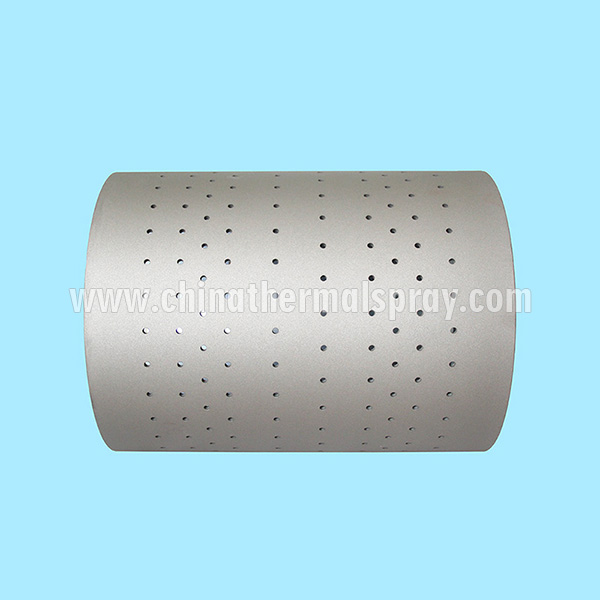

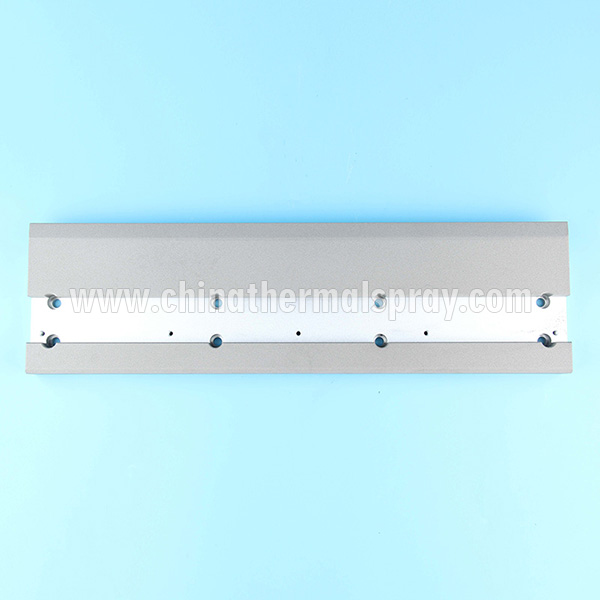

Mainly used in coating machines, printing machines, printing and dyeing machines, tape production machinery, diaper production machinery and other transmission rollers.

Mainly used in coating machines, printing machines, printing and dyeing machines, tape production machinery, diaper production machinery and other transmission rollers. Usually, some drive rollers of these equipments need to contact the glued surface, printing surface or printing surface, and the undried printing surface and printing surface are easy to contaminate the roller and affect the surface pattern of the product.

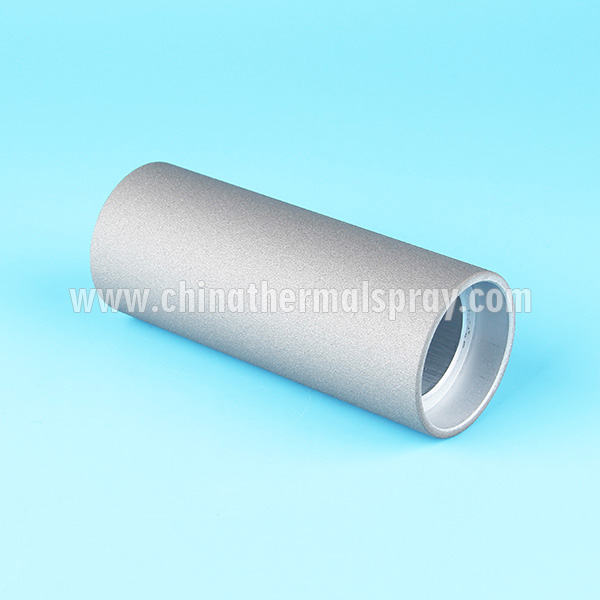

Stripping strength of traditional anti-sticking coating "Teflon" is too strong for hot melt adhesive. That is the anti-sticking performance and wear-resistance is not too good which led anti-sticking performance will lose effect in a short time. It will lead to low production efficiency, short maintenance cycle and high cost.

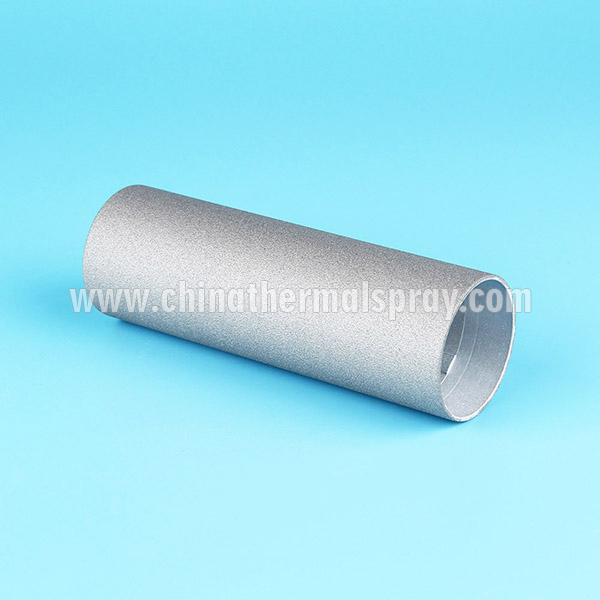

The invention patent independently researched and developed by our company "thermal spray anti-stick wear-resistant coating" adopts plasma thermal spray technology, uses nickel-based alloy dispersion bond polymer anti-stick material, and uses bionics "Lotus leaf effect", the coating has extremely low adhesive peeling force and excellent wear resistance, and the overall performance is dozens of times higher than that of Teflon coating, reaching the national leading level in this field.

Related products

-

Small Scale PE PP HDPE LDPE Films Bags Rigid Plastic Granulators Recycling Pelletizing Machine

Contact UsThis is multifunctional small plastic pelletizing line. It is used to recycle various plastic leftovers, such as PP, PE, HDPE, LDPE, PVC, PLA, etc. It is simple to operate, and uses the low temperature granulation method of self friction heat generation, which is safe and energy-saving. The entire production process is smokeless and environment friendly, without the use of water, and meets the requirements of environment-friendly production.

-

General Rotogravure Printing Machinegghgh

Contact UsOur Printing Machine is a high-quality printing device that is designed to meet the printing needs of various industries. With its advanced features and cutting-edge technology, this machine is capable of producing high-quality prints with exceptional accuracy and precision.Our Printing Machine is a high-quality printing device that is designed to meet the

-

20KVA/16KW Diesel Generator With Cummins Engine

Contact UsOur 16KW 20KVA diesel generator with Cummins engine is ideal for reliable power solutions.

-

Used NSC Schlumberger GC14 Gilling Machine

Contact UsYear: 1996

Spinning production line

Mixed strip: GC15 barrel diameter 1000 * 1200mm, 1 head and 1 barrel, automatic barrel change

One stitch: GC14 cylinder diameter 1000 * 1200mm, 1 head and 1 barrel, with self leveling and automatic barrel changing

Two needles: GC14 cylinder diameter 700 * 1200mm, two heads and two barrels, automatic barrel changing

Three needles: GC14 cylinder diameter 600 * 1200mm, 4 heads, 2 barrels, automatic barrel change

According to your requirements, we can transform it into a suitable size for your production needs!

Reviews

There are no reviews yet.