VMC 955 Vertical CNC Machining Center

The whole machine is designed with fully enclosed outer cover for better waterproofness. The three axes adopt heavy-duty roller line rail, which makes the machine have high speed, high precision.

https://www.josencnc.com/VMC-955-CNC-Vertical-Machining-Center.html

The machine is suitable for medical equipment, aviation, communication electronics and other fields. The whole machine is designed with fully enclosed outer cover for better waterproofness. The three axes adopt heavy-duty roller line rail, which makes the machine have high speed, high precision as well as high rigidity. The bottom adopts three-way chip discharge design, which makes the reliability of the base chip discharge better.

1.This type of automobile and locomotive parts of the mass production needs,

medical equipment, aviation and communication electronics, various types of

precision mold processing production.

2.The casting structure is analyzed by machine dynamics and finite element

analysis, which makes its geometry more reasonable, and the proper match with

the reinforcement bones ensures the high rigidity of the base parts.

3.The whole machine is designed with fully enclosed outer cover for better

waterproofing, and the chassis is directly sitting on the base, which reduces

the problem of leakage from the floor and ensures the cleanliness of the

workshop.

4.The X-axis saddle is designed with inverted structure, which makes the

center of gravity more stable and the bearing contact surface more solid, and

the one-piece design of bearing seat and saddle, combined with precision

machining and high-quality assembly process, ensures smooth parallelism.

5.The bottom adopts three-way chip discharge design, with the combination of

large inclined plate and large flow pump, which makes the chip discharge of the

base excellent and reliable.

| ITEM | UNIT | CV-955S |

| Travel | ||

| X-axis travel | mm | 900 |

| Y-axis travel | mm | 520 |

| Z-axis travel | mm | 550 |

| Worktable size | ||

| Working table size (X*Y) | mm | 1120×520 |

| Max.loading capacity of working table | kg | 500 |

| Table T-slot size (width * number of slots * spacing) | number | 18x5x100 |

| Spindle | ||

| Spindle speed | rpm | 12000 |

| Spindle drive form | Direct driven | |

| Spindle power | kW | 11/15 |

| Spindle bore specification | BT40 | |

| Distance from spindle to table surface | mm | 145-695 |

| Spindle feed | ||

| Rapid feed rate(X,Y,Z) | m/min | 36/36/36 |

| Cutting feed rate | mm/min | 10000 |

| Tool magazine | ||

| Tool magazine capacity | cutter arm type 24/30 | |

| Tool diameter/adjacent tool space | mm | Φ80/Φ150 |

| Max. Tool length | mm | 300 |

| Max. Tool weight | kg | 8 |

| Accuracy | ||

| Positioning accuracy | mm | ±0.005 |

| Reproduction accuracy | mm | ±0.003 |

| Others | ||

| Controller | 0i-MF/M80 | |

| Air pressure demand | kg/cm2 | 6 |

| Power demand | kVA | 30 |

| Machine weight | T | 5.5 |

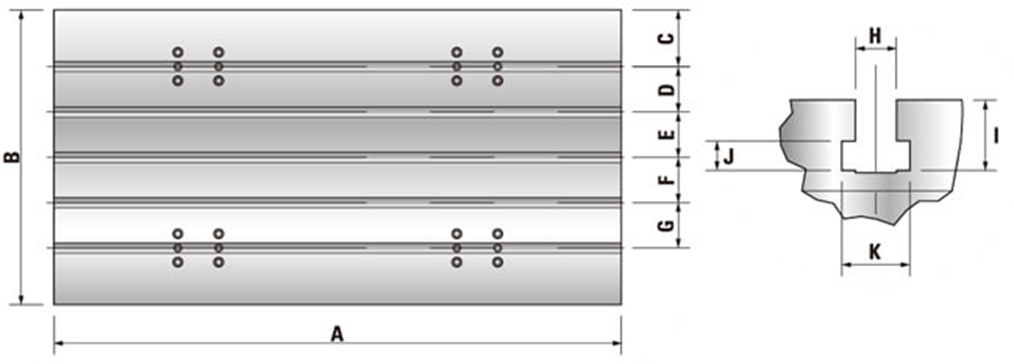

| Model | A | B | C | D | E | F | G | H | I | J | K | T-slot number |

| CV-955S | 1120 | 520 | 60 | 100 | 100 | 100 | 100 | 18 | 31 | 13 | 30 | 5 |

Related products

-

20KVA/16KW Diesel Generator With Cummins Engine

Contact UsOur 16KW 20KVA diesel generator with Cummins engine is ideal for reliable power solutions.

-

UT 1.6523/8620/20CrNiMoA Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Blockund Bar

Contact Us1.6523 Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Block/Round Bar

-

NEW GLASS SODA MAKER BEST CARBONATOR(GLASS BOTTLE) NEW ARRIVALS SODA STREAM MAKER HOUSEHOLD SPARKLING WATER MAKER WITH GLASS BOTTLE

Contact UsNEW GLASS SODA MAKER BEST CARBONATOR(GLASS BOTTLE) NEW ARRIVALS SODA STREAM MAKER HOUSEHOLD SPARKLING WATER MAKER WITH GLASS BOTTLE

-

Small Scale PE PP HDPE LDPE Films Bags Rigid Plastic Granulators Recycling Pelletizing Machine

Contact UsThis is multifunctional small plastic pelletizing line. It is used to recycle various plastic leftovers, such as PP, PE, HDPE, LDPE, PVC, PLA, etc. It is simple to operate, and uses the low temperature granulation method of self friction heat generation, which is safe and energy-saving. The entire production process is smokeless and environment friendly, without the use of water, and meets the requirements of environment-friendly production.

Reviews

There are no reviews yet.