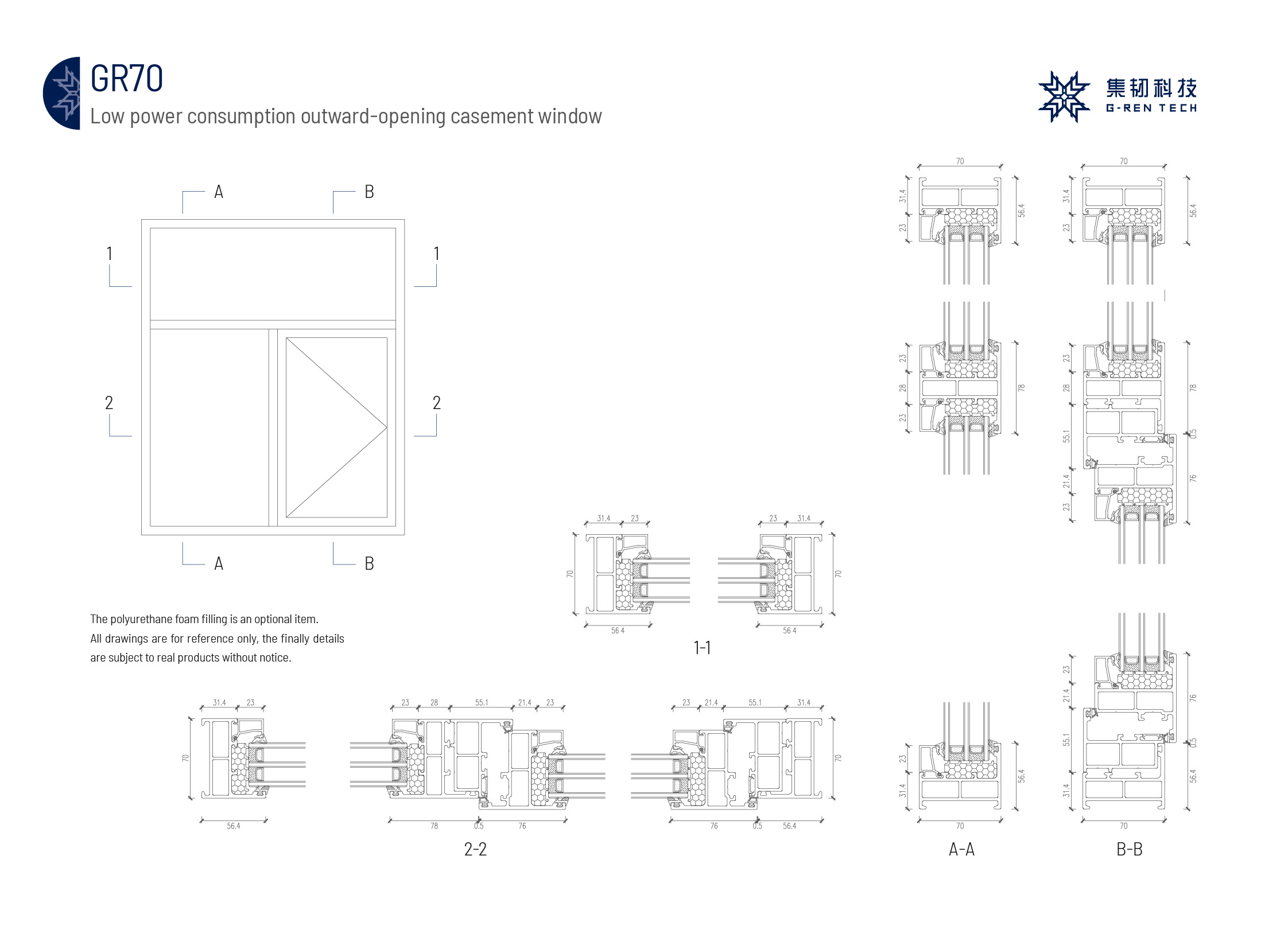

GR70 Low power consumption outward-opening casement window

Fiberglass reinforced polyurethane composite material is the high-performance composite material based on 20% polyurethane (PU) and 80% fiberglass (GF).

GR70 Low power consumption outward-opening casement window

Global door & window material innovation

Global door & window material innovation

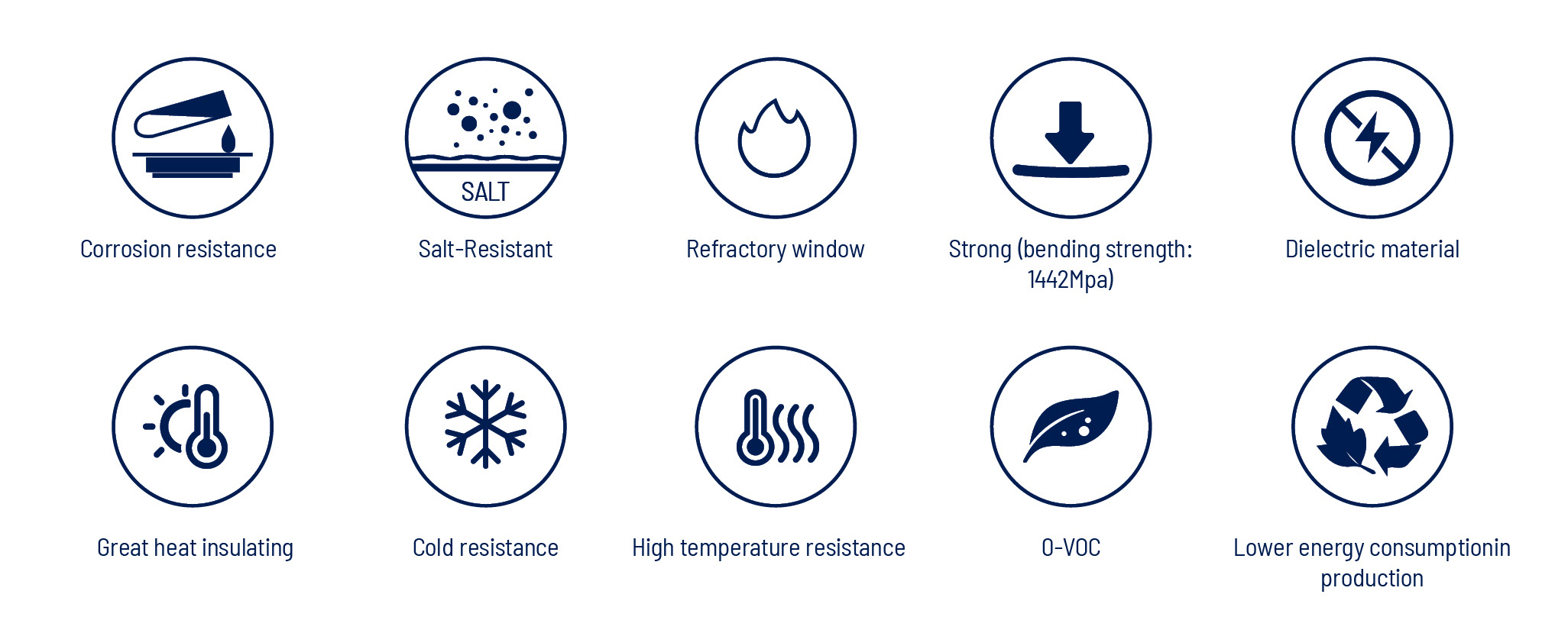

Characteristics of PU fiberglass composites

| Property | Aluminum Alloy | Steel | R PVC | Fiberglass Reinforced Plastic | Fiberglass Reinforced Pu |

| Density (g/cm³) | 2.7 | 7.8 | 1.4 | 1.8 | 2.2 |

| Bending strength (MPa) | 170-230 | 200~500 | 70~110 | 300~600 | 1442 |

| Bending modulus (GPa) | 68 | 200 | 2.2~5 | 10~22 | 44 |

| Tensile strength (MPa) | 200~300 | <670 | 35~52 | 300~600 | 1220 |

| Tensile modulus (GPa) | 68 | 200 | 2.2~5 | 20~25 | 56.5 |

| Strength-weight ratio (10³N·m/kg) | 74~111 | <86 | 25~37 | 333 | 581 |

| Thermal Conductivity (W/m·K) | >150 | 36~54 | 0.14 | 0.4 | 0.114 |

| Linear expansivity (10-5K-1) | 2.2~2.4 | 1.2 | 6~7 | 0.7~6 | 0.5 |

| Volume resistivity (Ω·m) | 2.9*10-8 | 9.8*10-8 | 1*1011-12 | 1*1012 | 1.5*1012 |

| Corrosion resistance (acid, alkali, salt) | Poor | Poor | Averagely | Excellent | Excellent |

Polyurethane Glass Fiber Composite (PU-GFRP)

Lightweight & High Strength: Density is just 1/6 of steel and 1/2 of aluminum, yet delivers exceptional strength and toughness.

Superior Corrosion Resistance: Excels in harsh environments (salt spray, acids/alkalis, humidity).

High Design Flexibility: Formula adjustments enable customized hardness, elasticity, color, and surface textures to meet specific needs.

Fiberglass reinforced polyurethane composite material is the high-performance composite material based on 20% polyurethane (PU) and 80% fiberglass (GF).

PU fiberglass material combines the excellent toughness, fatigue resistance, impact resistance and processing flexibility of polyurethane resin, as well as the high strength, high rigidity and stability of fiberglass.

Formed through efficient processes such as pultrusion and winding, it features light weight and high strength, thermal insulation, corrosion resistance, and environmental friendliness, and its mechanical properties can be comparable to some metal materials.

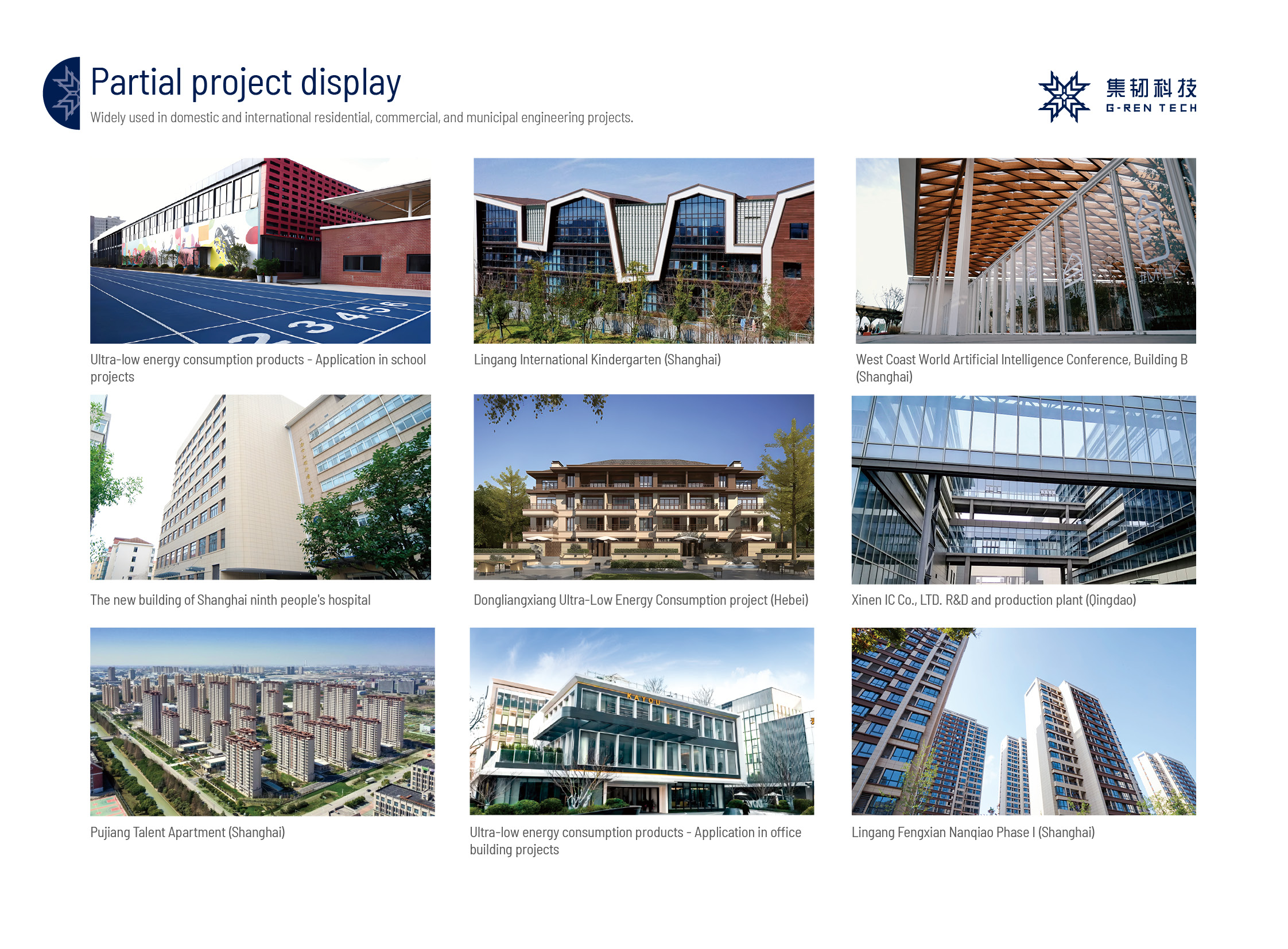

Due to its many excellent properties, PU fiberglass composite material is widely used in multiple industrial fields such as door and window curtain wall systems, wind energy, photovoltaics, new energy vehicles, medical equipment, engineering equipment, aerospace, etc., and gradually replaces metal and traditional plastic materials.

Related products

-

Axial type roof fans

Contact UsAxial roof fans are used in pressurization fan, fresh air fan and smoke exhaust fan applications. The enclosure is fire resistant and designed according to the noise standard.

-

Multi-functional Food Trucks

Contact UsWhether it’s for outdoor events, street food, or family gatherings, this versatile food cart is designed to meet all your needs.

-

Clear View

Contact UsET Station Limited,紮根香港十五載,是大灣區備受推崇的專業貼膜服務商。我們的總部優雅坐落於新界大埔山燕路8號Grand Palisades,交通便利,環境舒適。多年來,我們始終秉持精益求精的工匠精神,為香港本地、內陸及整個大灣區的尊貴客戶提供卓越的貼膜解決方案。

作為行業先驅,我們專營XPELVision家居建築保護膜系列產品,這些高科技膜材不僅能有效隔熱隔紫外線,還能提升居住空間的舒適度與安全性。我們的建築貼膜產品適用於住宅、商業空間、辦公樓等各類建築,可有效降低能源消耗,保護室內傢俱不受陽光損害,同時保持室內私密性。

憑藉十五年專業技術積累與不懈創新,ET Station Limited已發展成為業內享有盛譽的貼膜專家。我們的技師團隊經過嚴格培訓與認證,熟悉各類建築結構和玻璃特性,能夠提供最適合您需求的貼膜方案。我們使用先進的施工工具和技術,確保每一次貼膜都完美無瑕,經久耐用。

憑藉十五年專業技術積累與不懈創新,ET Station Limited已發展成為業內享有盛譽的貼膜專家。我們的技師團隊經過嚴格培訓與認證,熟悉各類建築結構和玻璃特性,能夠提供最適合您需求的貼膜方案。我們使用先進的施工工具和技術,確保每一次貼膜都完美無瑕,經久耐用。 -

Stainless Steel Water Separator

Contact UsYuehua brand stainless steel pressure pipes and fittings are manufactured from stainless steel plates sourced from renowned steel mills such as Posco, TISCO, and Yongjin.

Reviews

There are no reviews yet.